Algrip – An Investment in Safety

Safety

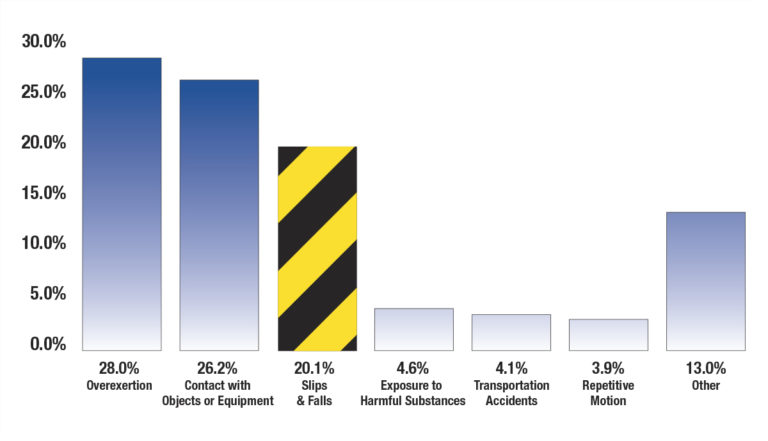

The United States Bureau of Labor Statistics reports that over 20% of all compensable industrial injuries result from slips and falls. Often these accidents occur when liquids, lubricants or foreign materials have accumulated on floors, stairs or work platforms.

For these challenging applications, the unique matrix application of Algrip laser deposits provides unparalleled slip resistance in all directions. Plate products are manufactured with more than 1,000 deposits per square foot. Shoe and tire materials completely encircle and “grab” the deposits. Worker safety and employer protections are significantly enhanced with each installation of Algrip.

Risk-Reward Analysis

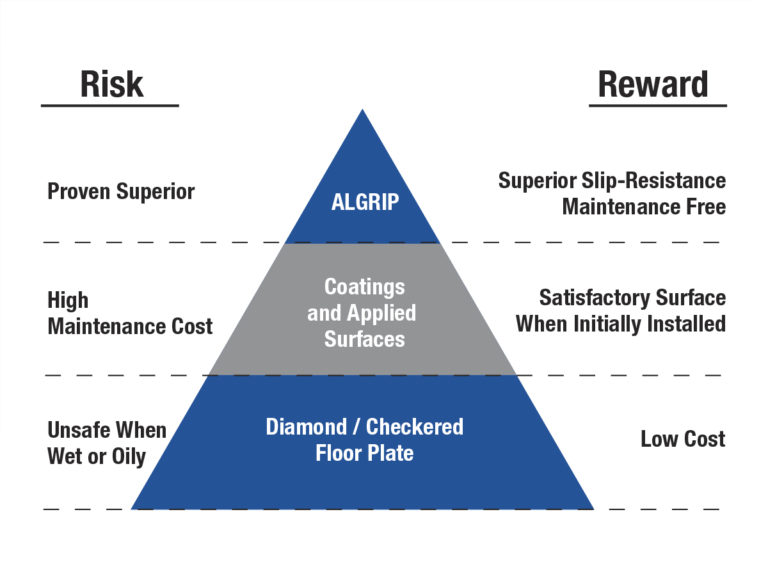

When considering any investment, there are options. Safety flooring products are no exception. The risk-reward pyramid for safety flooring starts with common diamond/checker floor plate. This product is inexpensive, but provides little or no safety when wet or oily. The cost is low, but the risk is high.

The second level of the pyramid relates to floors that have been treated with coatings or applied surfaces. These hybrids provide a fair level of safety when initially installed but often create a maintenance burden. When subjected to wear, applied coatings can quickly deteriorate. Applied surfaces can crack or de-laminate when subjected to service loads. To maintain safe working conditions with these products, there is often a continuous and costly maintenance cycle.

When you invest in Algrip, you have selected a superior safety floor surface that is virtually maintenance free. Once installed, employees and employers are provided the highest level of protection from slips and falls. Supervisors can focus their attention on smooth plant operations rather than recurring maintenance. With Algrip, you are at the Top of the Pyramid!

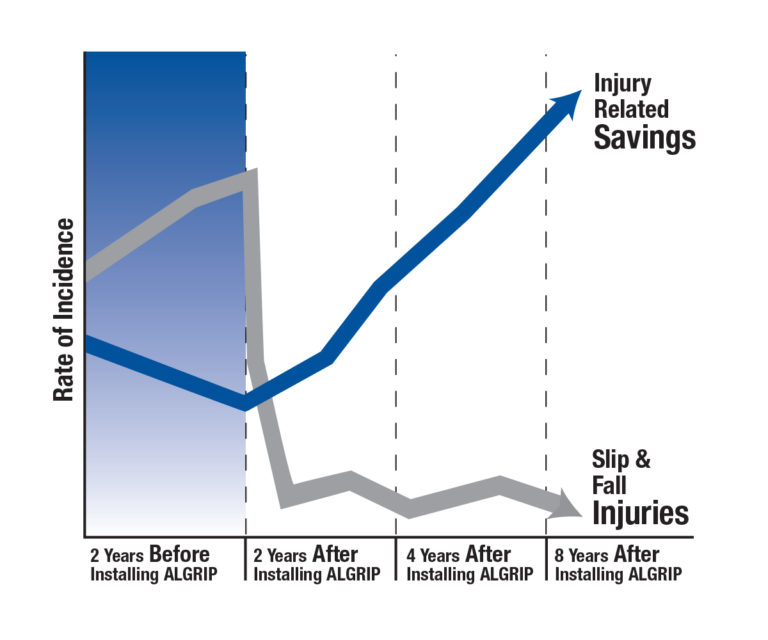

Return on Investment

When considering any investment, there are options. Safety flooring products are no exception. The risk-reward pyramid for safety flooring starts with common diamond/checker floor plate. This product is inexpensive, but provides little or no safety when wet or oily. The cost is low, but the risk is high.

The second level of the pyramid relates to floors that have been treated with coatings or applied surfaces. These hybrids provide a fair level of safety when initially installed but often create a maintenance burden. When subjected to wear, applied coatings can quickly deteriorate. Applied surfaces can crack or de-laminate when subjected to service loads. To maintain safe working conditions with these products, there is often a continuous and costly maintenance cycle.

When you invest in Algrip, you have selected a superior safety floor surface that is virtually maintenance free. Once installed, employees and employers are provided the highest level of protection from slips and falls. Supervisors can focus their attention on smooth plant operations rather than recurring maintenance. With Algrip, you are at the Top of the Pyramid!