Banding Products & Features

Banding

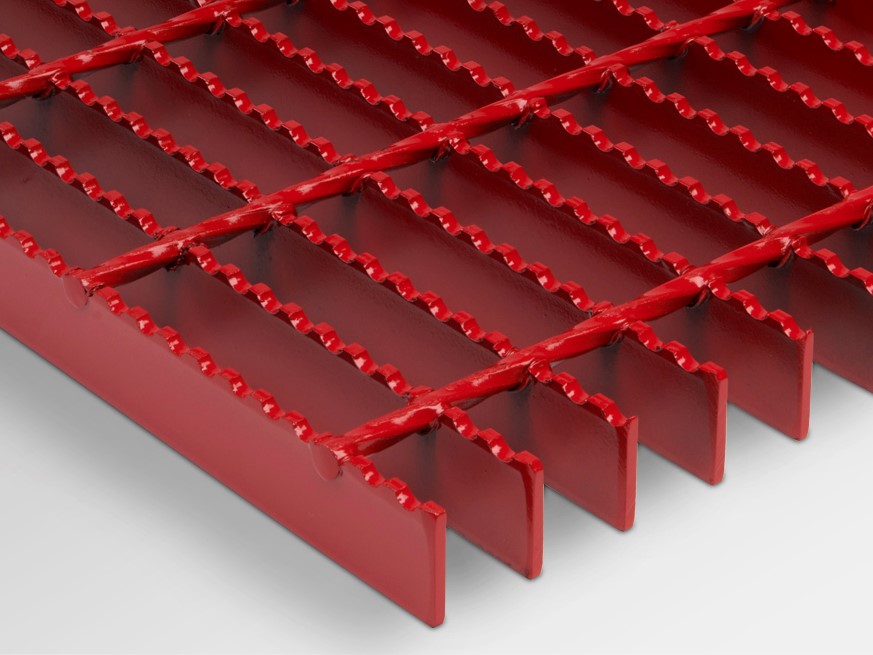

Banding is an option to protect the open ends of the grating panel. Banding may be specified on any grating product. During the banding process, a metal flat bar is welded to the open ends of the grating panel. Certain applications benefit significantly from banding which provides additional transverse stiffness and a finished architectural appearance.

Banding should always be specified for the following applications:

- Removable grating panels – Closed ends provide additional worker safety during handling.

- Vehicular load exposure – The band bar helps reduce impact stresses by transferring loads to adjacent bearing bars thus increasing resistance to grating deformation caused by repetitive traffic patterns on open ended grating.

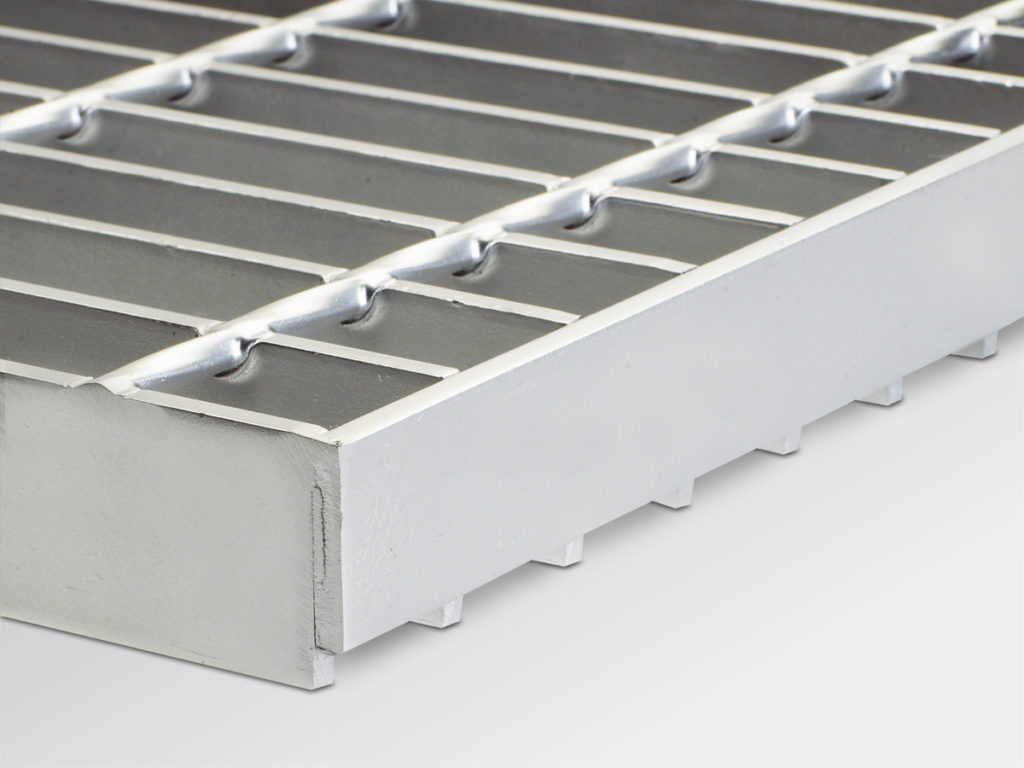

Trench banding is an additional option where the band bar is elevated above the bottom of the bearing bars. The elevated band bar is ideal for drainage applications as it allows for pass through of liquids and will not trap liquids between the band bar and the grating support.

Open Ends as Manufactured

Standard Trim Banding

Trench Banding

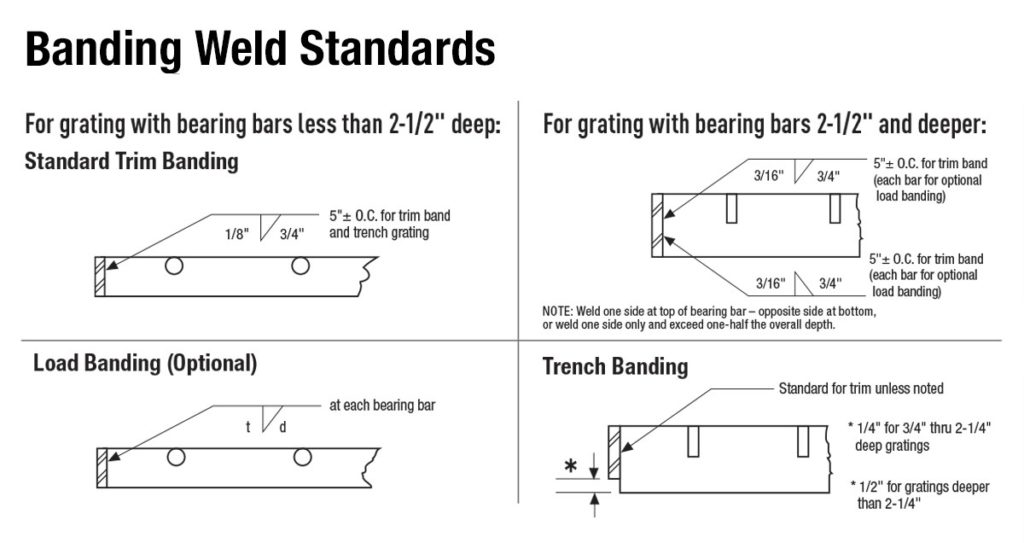

Welding Standards

Banding welding options include Standard Trim or optional Load Banded (details illustrated below). Standard trim banding provides for welds +/- 5” on center and provides a uniform end to each piece. Load banding has welds at each bearing bar which helps distribute the load throughout the grating panel in addition to providing the uniform end finish.