Fastening Metal Bar Grating

All grating must be firmly secured in place. This is typically accomplished by welding or the use of bolted mechanical fasteners.

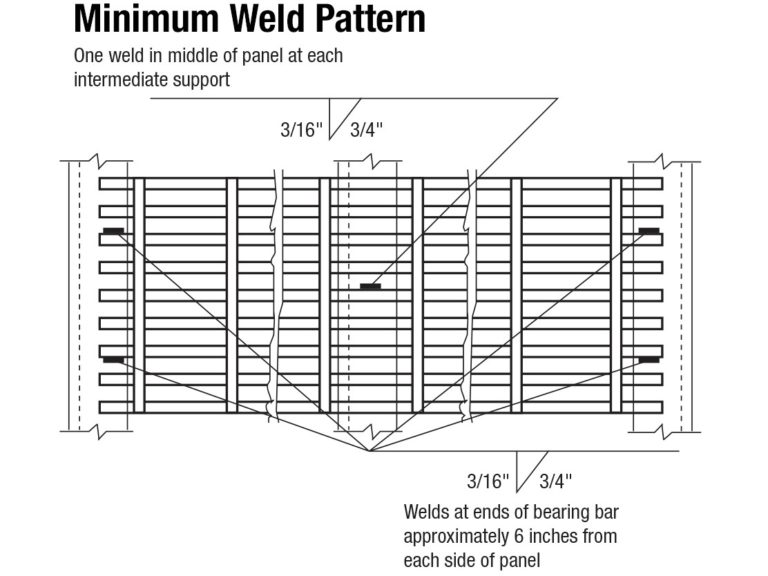

Welded Installation

Welding will provide a superior, permanent installation, while mechanical fasteners are available when the grating needs to be removable or welding is not practical.

The recommended minimum weld pattern to the right also indicates the minimum fastener spacing for pedestrian applications.

Vehicular applications typically require additional welding, size, and spacing determined by the specifying authority.

Bar Grating Fasteners

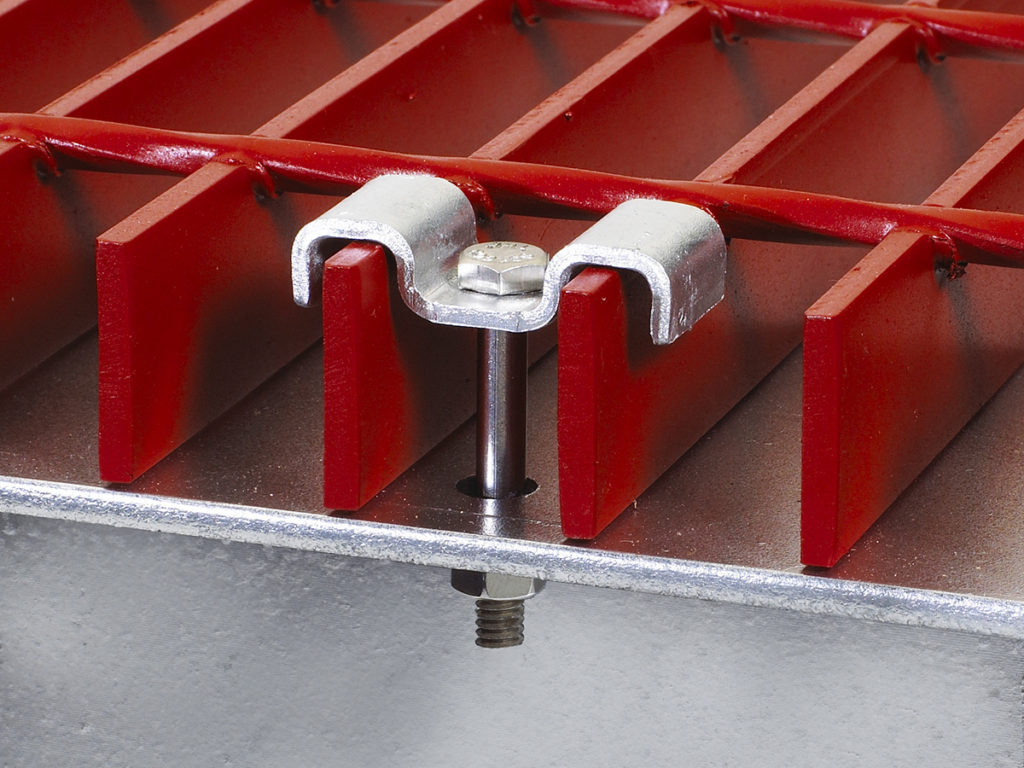

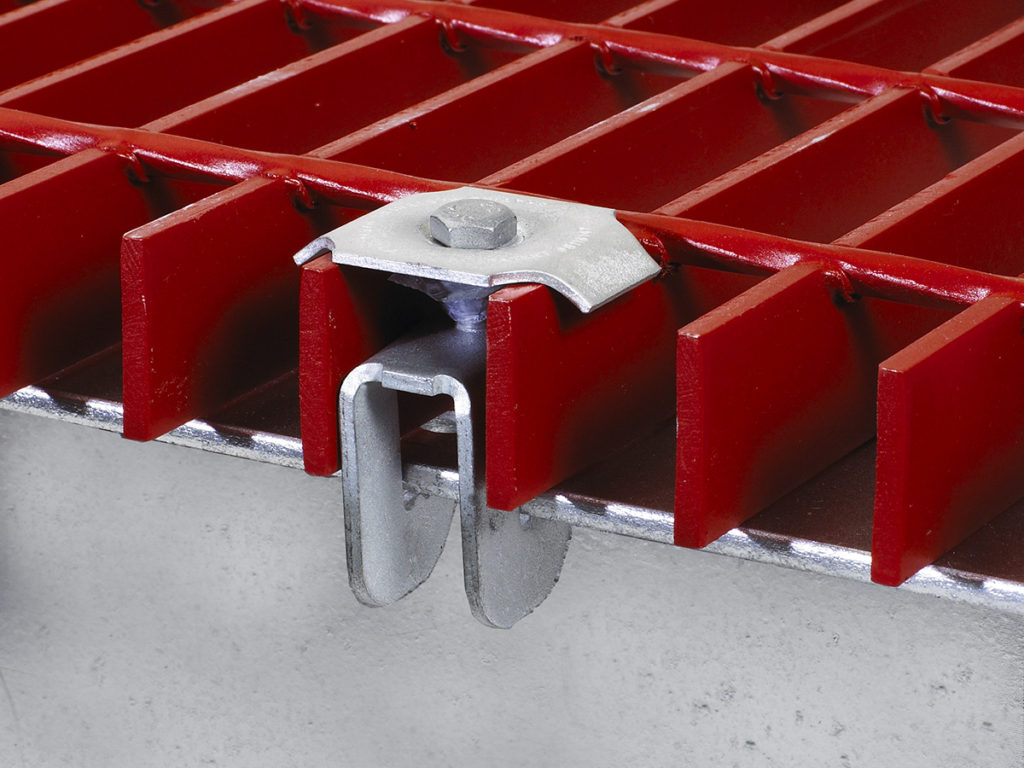

Saddle Clips

Bent clips bridging two bearing bars are available in galvanized steel, stainless steel, or aluminum. Standard bolt holes are 5/16″. Bolts, screws, or other connecting hardware shall be supplied by others.

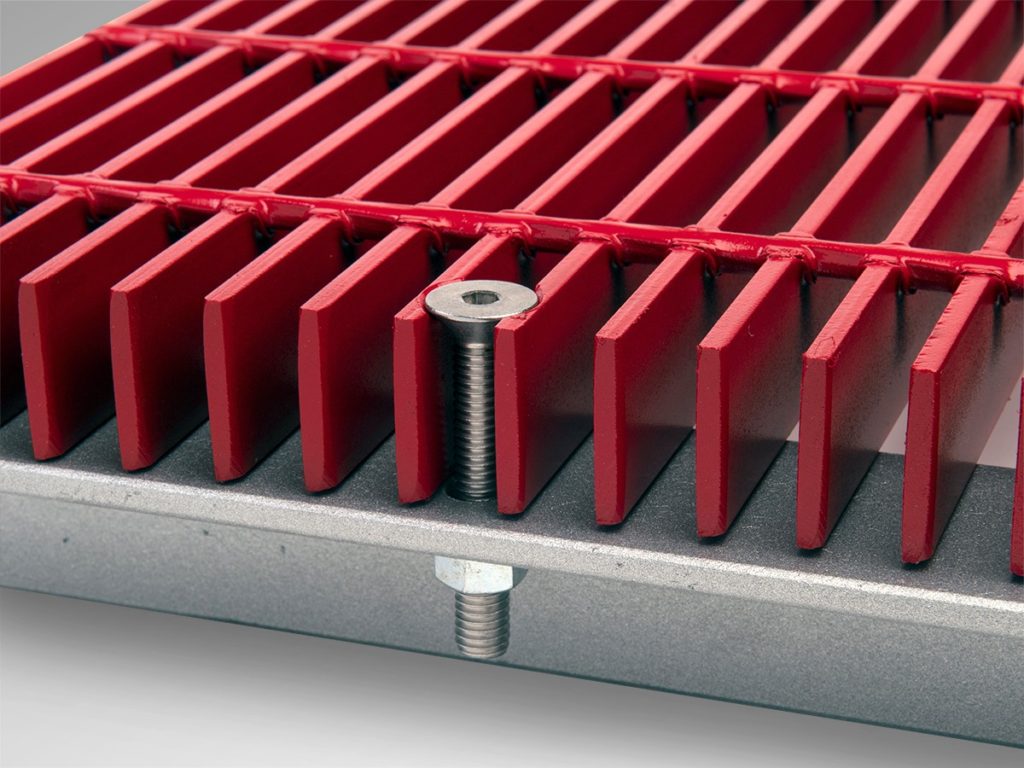

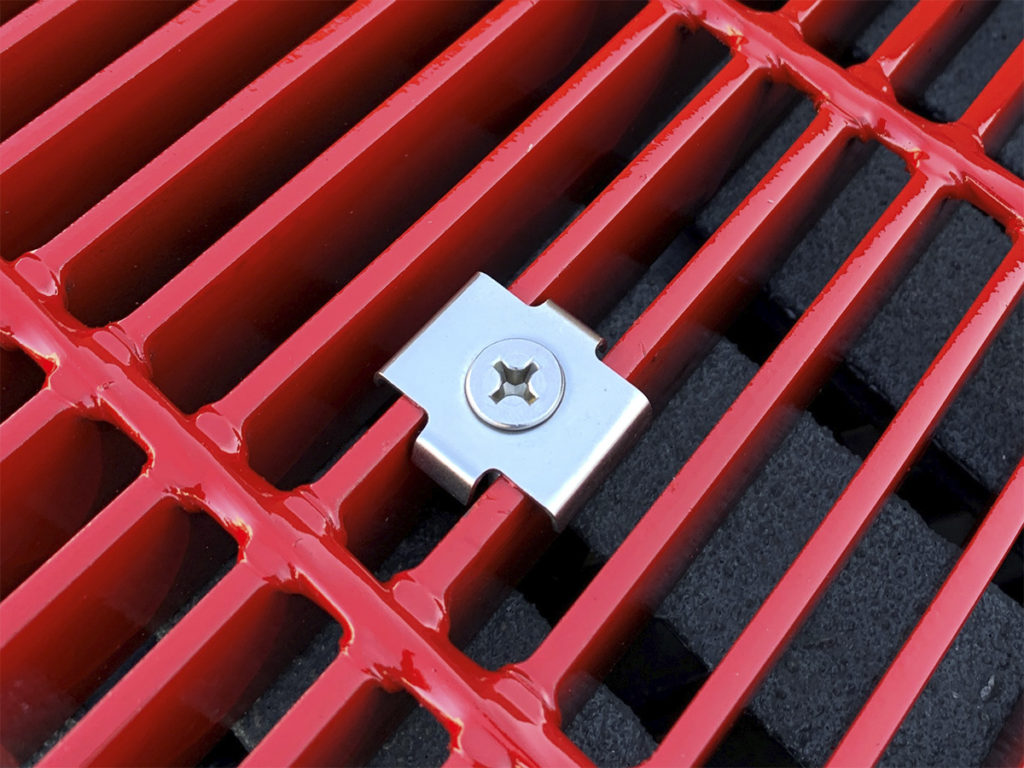

Countersunk Lands

The narrow spacing of close mesh grating allows for countersinking or milling of the bearing bars to support bolt shoulders. Flat head screws or self-drilling fasteners shall be supplied by others.

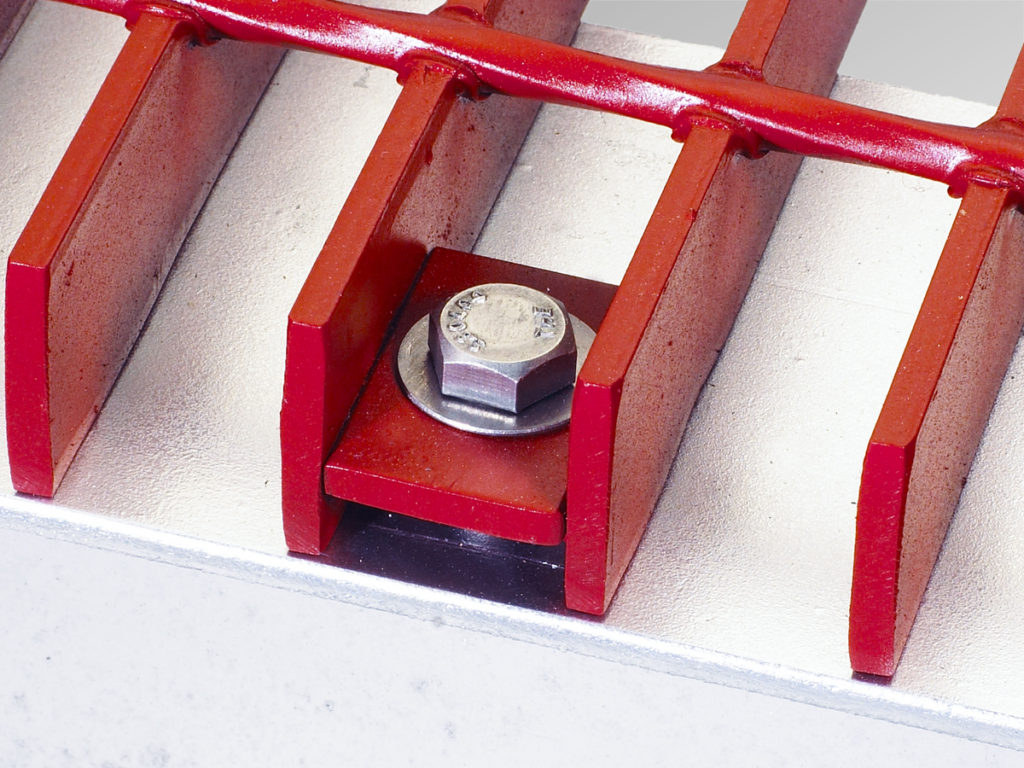

Weld Lugs

Plates, punched with holes and welded between the bearing bars, facilitate bolting to the supporting structure. Bolts, screws, or other connecting hardware shall be supplied by others.

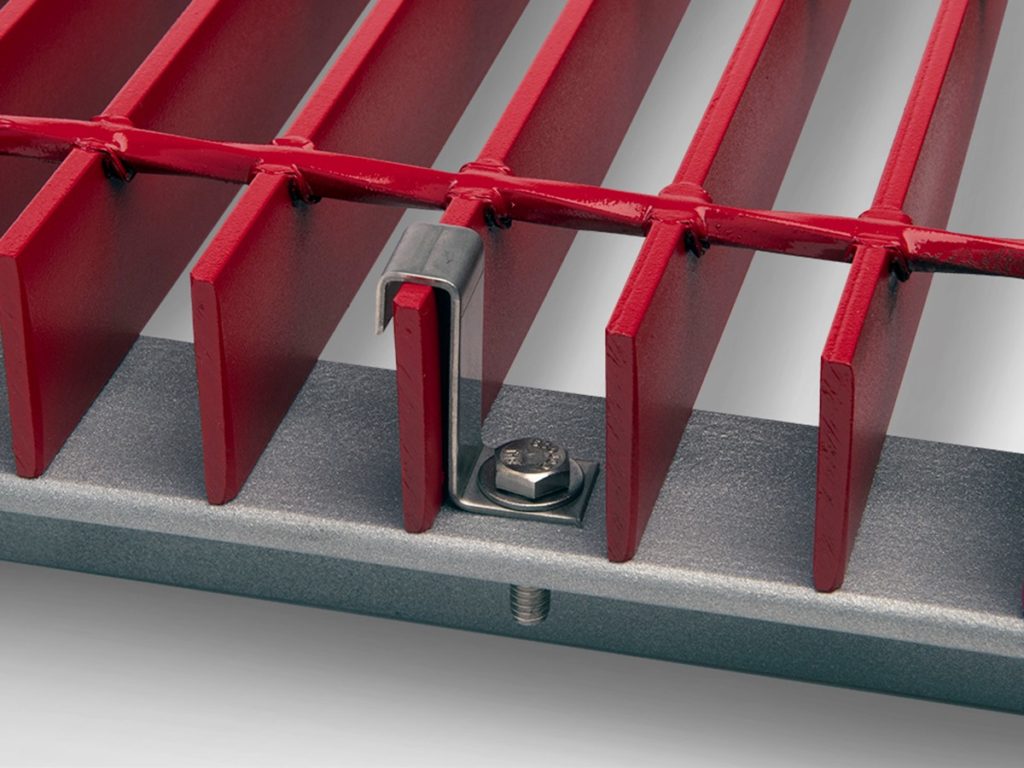

“G” Clips

Mechanical fasteners installed from the top surface of the grating create a friction connection with the flange supporting the panel. “G” clips are easily installed without drilling or welding.

“E-11” Clips

Formed clip captures two bearing bars spaced at 11/16″ on center. Flat countersunk screws and other fastening hardware shall be supplied by others.

“J” Clips

Narrow formed clip captures one bearing bar when spacing is limited, frequently 11/16″ on center. Cap screws and other fastening hardware shall be supplied by others.